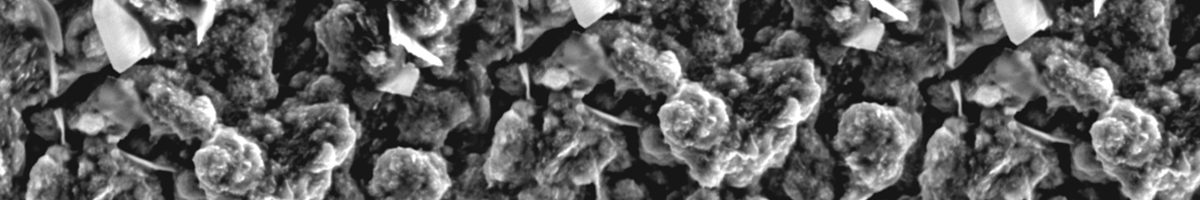

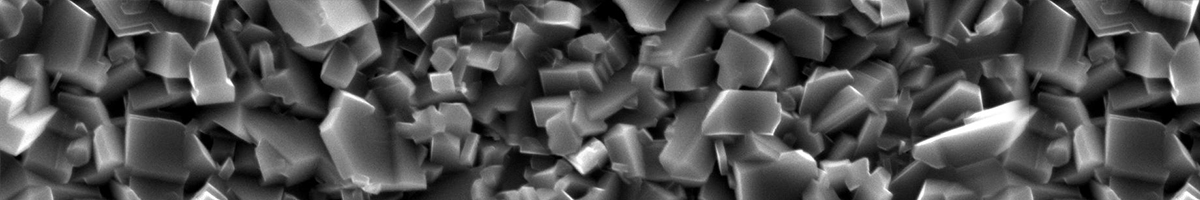

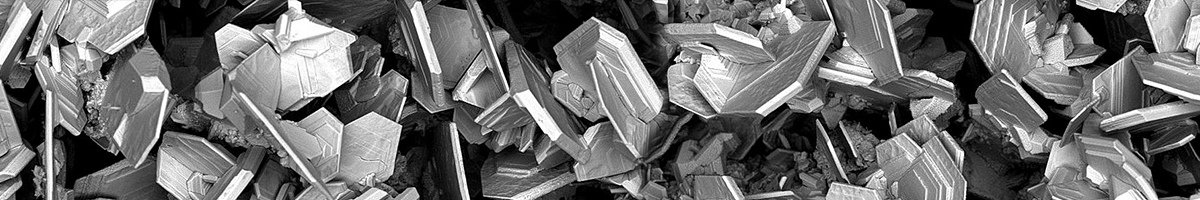

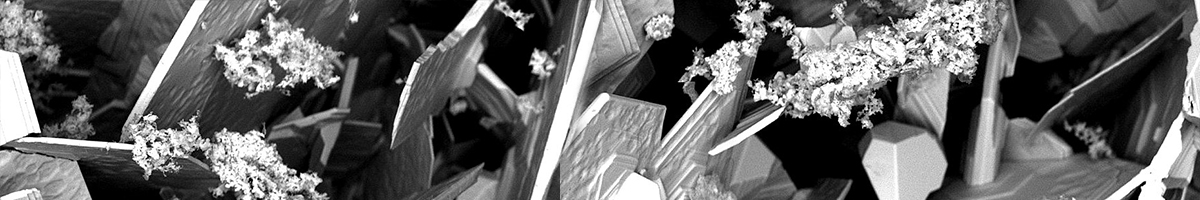

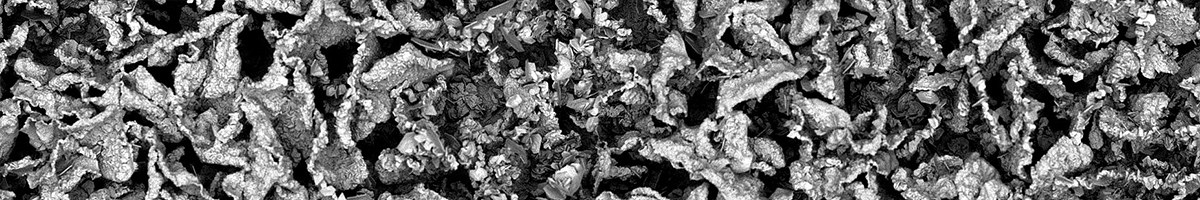

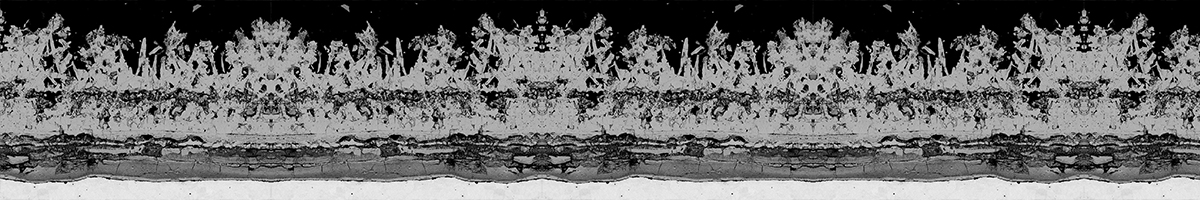

Development mechanism of thermodynamically stable, thin and protective oxide scales formation at high temperatures in pure water steam on the alloys based on Fe and Ni structures with high chromium content.

Scientific development

Dr. Tomasz Dudziak (D.Sc.)

Master and bachelor degree (MSc, BSc),dissertation written in English entitled: “Interdiffusion platinum, rhodium, and rhenium in -NiAl”. Graduated in 2005, Faculty of Material Science and Ceramics, Solid State Chemistry Department, Stanislaw Staszic University Science and Technology, Krakow, 2005.

PhD Degree

Doctor of Philosophy (PhD degree in 2010), PhD Thesis entitled “High temperature corrosion studies and interdiffusion modelling in TiAl based alloys coated with high performance surface layers”, Northumbria University at Newcastle upon Tyne, Computer Engineering and Information Sciences (CEIS), The United Kingdom, the work was supervised by: Prof. Prasanta Datta. The work was dedicated to high temperature corrosion studies of g-TiAl alloy (Ti-45Al-8Nb) and interdiffusion modelling studies using DIFSIM software. The high temperature corrosion research was carried out in temperature range 650 – 950 oC for 1000 and 5000 hours in different atmospheres including H2S/H2/H2O with pS2 = 10-1 Pa and pO2 = 10-18 Pa. In order to enhance corrosion resistance the base material was coated with a thin coatings using HIPIMS (High Impulse Power Magnetron Sputtering) process. The research performed during PhD studies were published in 10 papers listed in Journal Citation Reports (JCR) list.

D.Sc. degree

The D.Sc. degree was awarded in 2019 at the Warsaw University of Technology, at the Faculty of Materials Science and Engineering (The Best Engineering Studies in 2020 in Poland). The D.Sc. thesis covered the issues related to the high temperature corrosion of the materials for the power plant industry in Poland, both in water vapour (steam oxidation) and in fireside conditions (an atmosphere of aggressive gases and ashes).

Employment

2009 – 2012

Professional carrier I started after my graduation in Newcastle upon Tyne. during my PhD degree in the United Kingdom. I was employed in Cranfield University, School of Applied Science, at Centre for Energy and Resource Technology (CERT) as research fellow. During this stage (2009 – 2012) I was involved in 2 projects related to corrosion of the materials (ferritic steels, austenitic steels, Ni based alloys) in power plant industry (steam oxidation and fireside corrosion): SUPERGEN PLE 2 (www.supergenple.net) “Life Management of Efficient Fossil Power Plant” and ASPECT entitled. “Advanced Surface Protection to Enable Carbon Abatement Technologies”. In addition during this stage I was responsible also for research for Rolls-Royce plc. Derby UK where TiAl alloys coated with different protective coatings. The project was related to exposure of the samples with Na2SO4 + NaCl deposit in SO2 atmosphere for 500 hours.

2012–2013

I was employed in Cranfield University, School of Applied Science at Surface Engineering Nano Technology Institute (SENTI) on research fellow position. During my stay, I was involved in two projects (SAMULET 2, WING) commissioned by Rolls-Royce plc. Derby UK. High temperature research was oriented to investigate Thermal Barrier Coatings (TBC) resistance for thermal changes with CMAS deposit. The research was conducted at 1250 oC, in the tests 12 different coatings were tested, the coatings were different in the matter of chemical composition and grain size. The analyses were performed using standard procedure including Scanning Electron Microscope (SEM) coupled with Energy Dispersive X-Ray Spectrometry).

Scientific career in Poland

In 2013, I started my scientific career related to high temperature corrosion resistance in the Foundry Research Institute in Krakow at the Centre for High Temperature Studies. At the Centre for High Temperature Studies (Currently Łukasiewicz Research Network – Krakow Institute of Technology). In 2016 I was nominated for Head of Department, Centre for Design and Prototyping, in 2018 I was nominated by Jadwiga Emilewicz: head the Ministry of Entrepreneurship and Technology. This position I was held for almost 2 years. Currently I am responsible for Scientific Development and Scientific Mobility in Łukasiewicz Research Network – Krakow Institute of Technology, also I am the leader of High Temperature Corrosion Processes. Furthermore, I am involved in a reviewer role in Corrosion Science and in Journal of Materials Engineering and Performance (over 50 papers reviewed). Finally I am Topic Editor in Materials and Coatings MDPI Journals, I am Editor in Chief of Journal of Applied Materials Engineering (JAME)